|

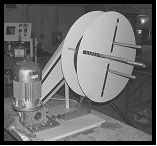

The Fully Automatic Dereeler comprises of three

parts

Motorized Dereeler

Dancer roller assembly

Control panel

A. The dereeler comprises of fabricated

stand to hold

the bobbin. The bobbin is

having certain adjustment

to hold your

wire/ sleeve bundle. A gear motor

powers the bobbin shaft. Motor is

controlled by a

Vector drive. (VFD).

B. The wire /sleeve is passed through a dancer roller assembly.

This assembly is

having electronic proximity sensors mounted on it. These sensors generate

start

and stop signals for the motorized dereeler.

C. The control panel provides the user

the option of running the dereeler in auto as

well as manual mode. It is also having a speed adjustment facility. In

addition, it also

provides a re-wind feature.

In

case of sleeve/wire jamming, the panel can send a

potential

free signal (change-over contact) to the wire/sleeve cutting

machine, which can be used to

stop the machine

|

The automatic dereeler will ensure that the

wire/sleeve is supplied only

when it is required. This will

require very minor attention of the operator. |

|

| |

|

|

| |

|

|

|

Home |

Products |

Enquiry | |

|